News Archives - Brij Encapsulants (India)

With over 500MW laminations, Brij Encapsulants have withstood the tests of time and quality. Contact us today for details.

Certified solution

Proven Quality

Lifetime reliability

Trusted technology

May the blessing of Shree Ganesha be with you and your family forever!

Brij Encapsulants wish you all a very Happy Ganesh Chaturthi!

Going solar also helps you better forecast and manage your expenses!

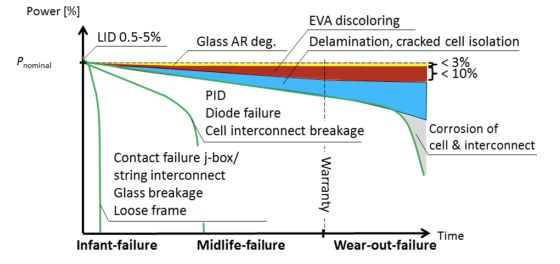

One of the significant factors in minimizing the costs of photovoltaic systems is to enlarge the integrity or dependability and the lifelong service of the PV modules. Solar modules are used to undertake raspy environmental hassles due to the persistent disparities of temperature and humidity. Also, the modules have to hold out for 25 years in such conditions with a maximum of 20% degradation in power to qualify most of the applications. Hence, it is requisite for manufactures to grab all possible provisions and care. At the same time, manufacturing also understands any defects in advance to ensure long-term durability and constant process improvement.

According to the International Energy Agency, the obstacles in solar PV modules can be classified as early failure, midlife failure and wear-out failure. Each category is described in detail as follows:

1.Infant or Early failure

Infant or Early failures usually arise in the initial period of a PV module. This prototype classified errors such as contact failures, string disconnects, loose frames, glass breakage, etc., are classified under this prototype.

2.Midlife Failure

The defeats or failures that occur within 10-15 years of operation are termed midlife failures. It majorly involves failures such as potential instigate degradation, Diode failure, Glass degradation, etc.

3.Wear-out Failure

Wear out failures arise due to declining processes or mechanical wear, and its chances of occurrence increase with time. It consists of issues such as corrosion of cells, occurring late in module lifetime, etc.

Some of the other failures that can be occurred are packaging material degradation or semiconductor device degradation.

1.Packaging Material Degradation

In packaging material degradation, defects such as breaking of glass, cracking of back sheet, failure of bypass diode can be included.

Now let’s discuss some of the packaging material degradations:

-

Encapsulant Degradation

The immense exposure of the solar modules to the light results in the humiliation of the encapsulant, Degradation of EVA, upon subjection to UV rays and high temperatures. It causes discoloration and produces acetic acid that can further dissolve the metallization on solar cells.

-

Diode or Junction box failures

Suppose the formation of the junction box is not efficient or the sealing is not relevant. In that case, rainwater can get into the terminals and corrode them, directing to higher series resistance, less power output and electric fires.

-

Backsheet degradation

Backsheets are the primary line of defence for PV modules. Besides any physical damage, its humiliation is majorly caused due to the high exposure of direct UV in the front and reflected UV at the back, which can lead to cracking, delamination, etc.

-

Loss of Adhesion

Ethylene-vinyl acetate (EVA) is commonly used to protect the operating environment and acts as an adhesive between the front glass and back sheet.

-

Moisture Intrusion

Moisture can pierce a PV module from the overlaid edges or backsheet, thus result in corrosion and increased leakage current. Corrosion results in the failure of contact between the grid lines and cell, creating a loss in electrical performance.

-

Corrosion of interconnects

Commuting the structure of the solder joints due to the separation of metals in the bonding alloy results in interconnect degradation.

-

Increased leakage currents

Leakage currents engendered due to the interconnections or humidity approach can lead to high voltage safety issues, thus generating safety hazards.

-

Thermal degradation

The generation of lattice defects in the structure of the solar cells strikes the electrical properties of the cell. The temperature degradation mainly results in an increased series resistance and leads to the declination of the anti-reflective coatings.

-

Performance degradation

On account of stratum or delamination, the sunlight cannot get into the cells, resulting in performance degradation. These failures can also impact constant debauchery of heat evolving into higher operating cell temperature.

2.Semiconductor Device Degradation

-

Hot Spots

Hot spots happen in a module when its operating power exceeds the minimized short circuit power of a shaded cell within it. The failure of hotspots can lead to the non-uniform illumination of the module, individual cell degradation, etc.

-

Snail Trails

A snail track is a grey discoloration of silver paste on the screen-printed solar cells. The discoloring usually occurs within one year after installing the PV modules due to the moisture entrance through micro cracks.

-

Broken cell

Wafer slicing, cell production, hanging and other implanted process during the production of the solar cell can result in cell cracks. It can also lead to an output of the modules and float unwanted hot spots.

-

Potential induced degradation

Potential induced degradation occurs when the module’s voltage potential and leakage current drive within the module between the semiconductor material and other module elements, thus causing the module’s power output volume to degrade.

-

Striation Rings

Striations are growth actuated magnetization that hinders the applications of solid-solutions crystals in photovoltaic applications. They are majorly caused by transitive impermanence during crystal growth and are not revealed to impact area operations.

-

Light–Induced Degradation

Light-Induced Degradation (LID) usually occurs in lucent silicon cells in the initial hours of outdoor exposure and diminishes the short-circuit power by 1-5%. It generally attributes to boron-oxygen defects in the P-type wafer.

The list of field issues or problems can be limitless; however, a component needs to understand and acknowledge the essential ones for constant product improvement.

With more than 25 years of EVA processing experience and constant interactions with research organizations around the globe, the R&D team at Brij examines any issues. It ensures that every square meter of Brij EVA abbreviates solar modules for a lifetime.

“A brother is a friend God gave you a sister is a friend your heart chose for you” Happy Raksha Bandhan!

Certified solution ✅

Proven Quality ✅

Lifetime reliability ✅

Trusted technology ✅

Head Office

New Delhi – 110034