What are Quality Assurance and Standard Tests for EVA?

Product testing in any industry is a vital role to play product research and development. The process might look easy and simple, but in reality, it is not, the standard tests for determination of the quality of EVA are majorly varied and sometimes ambiguous. Hence the following tests are generally used to define the quality of the EVA encapsulant films.

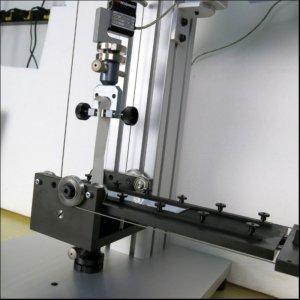

1.Peel strength (Adhesion test)

Peel Strength testing is a basic mechanical test technique that the peel separation strength of 2 flexible materials adhered or bonded together. It measures adhesion of EVA to the substrate, which is a vital factor indicating the durability and longevity throughout its operational lifetime and guarantees its excellent performance.

Low adhesion force leads to expiring EVA material or exposure to moisture or even improper laminating conditions during manufacturing.

Peel Strength testing is also a vital tool to determine the overall quality of the lamination. Values are between 75 N/cm and 125 N/cm can be used as a reference for quality control.

2.Gel Content Test

The objective of the method is to determine the gel content of the EVA. Gel content provides a means of both controlling the process and rating finished product quality.

EVA Gel Content test (known as a Crosslinking ratio measure) is a quality test of solar panel. The gel content of EVA is a degree of crosslinking in the polymer. Lower gel content can indicate a lower degree of crosslinking, which can severely jeopardize the solar module’s long-term mechanical integrity. The EVA Gel Content levels of 70% or higher are recommended for longer lifetime of solar modules.

Also Read: Why EVA Front Sheets are Important for Solar Module?

3.Thermal Shrinkage

EVA films shrink when they are heated at lamination temperatures. If it is not controlled, it will cause misalignment of strings, breakage of solar cells, and other issues. Shrinkage is generally observed due to process-induced stresses while manufacturing of EVA films.

However, the rule of ‘lower the shrinkage and better the encapsulant’ is not always accurate due to other trade-offs. Globally, shrinkage levels of 2% or less are acceptable and are known to cause no laminating problems.

4.Long Term Encapsulation and Protection

Ethylene-vinyl acetate (EVA) encapsulation materials have attracted a lot of attention due to their extensive solar cells applications. Nearly 80% of photovoltaic (PV) modules are encapsulated by EVA materials.

An observation of slight deterioration of any of the encapsulant properties will lead to impair the electrical output of the module. That is very important to provide a 25 to the 30-year working life of a solar module. Hence a good EVA film should possess high peal strength, low shrinkage, good gel content, and withstand the module tests and harsh environmental conditions with ease.

Brij conducts regular research and development and stays updated with the latest trends and updates to not miss anything productive. Our in-house testing laboratory and stringent quality checks ensure the maximum gain of life span for our products. Contact us today to understand more in details.