Considerations for selection of EVA Encapsulants

Ethylene Vinyl Acetate is an encapsulant for solar modules or cells. It is a copolymer film that is an essential sealant of photovoltaic solar modules to ensure reliability and performance.

Here the materials attract a lot of attention due to their extensive applications in solar cells. EVA materials encapsulate about 80% of photovoltaic modules. There are many advantages, such as good light transmittance and elasticity, low processing temperature, excellent melt fluidity, and adhesive property. In addition, the price is low, which makes it very suitable as a solar cell encapsulation material.

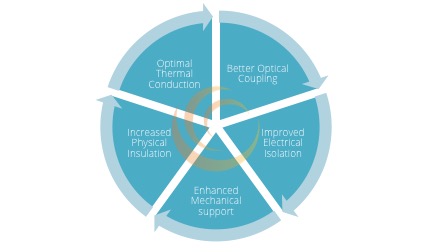

Along with these points, below are some essential criteria considerations for the selection of EVA Encapsulates

1.Optical Coupling

PV encapsulants optically couple PV cells to a transparent superstrate such as glass; therefore, high transmittance is desirable. The front side EVA forms the mid-layer between glass and solar cells, where the incident light passes this layer before reaching the solar cells.

An optimal refractive index direct through maximum light from the glass into the solar cells. An encapsulant should provide optical coupling of PV cells and protection against environmental stress. Polymers must perform these functions under prolonged periods of high temperature, humidity, and UV radiation.

2.Electrical Isolation

Solar modules need solid electrical isolation between the cell and other components. There is no concern of leakage currents which can then cause serious problem of potential induced degradation (PID), corrosion of interconnects and snail trails.

Encapsulants with high electrical resistivity, dielectric strength and lower water absorption rate keep leakage currents to a minimum and prove advantageous for the long life of modules.

3.Mechanical Strength

The motion of the soft, semi-elastic EVA layer upon pulling a mechanically “strong enough” backing foil on the EVA was critical to achieving the “apparent” adhesion strength.

The ultimate mechanical properties of EVA before and after crosslinking process are summarized as the most critical static mechanical properties like elastic modulus, strain-at-break and stress-at-break.

4.Thermal Conduction

PV modules can reach high operating temperatures (80°C-100°C) during operation. Without sufficient heat dissipation, the encapsulated solar cell can run at temperatures significantly higher than the ambient temperature reducing its performance and efficiency.

By ensuring high thermal conduction, a quality encapsulant provides the low-temperature operation of modules and gives better efficiency and long-term performance.

5.Physical Insulation & Protection

A solar module is an accumulation of connected series of solar cells electrically, producing the desired output. Less the movement of cells and firmly adhering to cells, EVA ensures both physical and electrical isolation between adjoining cells and busbars. It will also help in preventing short circuits, localized heating and hot spots.

Backed by more than 25 years of EVA processing experience and understanding of the product and the technology, our expert team will be happy to give you advice. Connect Brij today, and we will help you with your queries regarding consideration for selecting EVA Encapsulants.